Our Innovation

T.E.S.T.

Tubular Evaluation System Technology

Streamlined inspection efficiency:

Utilize existing techniques widely proved in other industries

Consistent result – Reliable processes and procedures result in accurate and subjective results.

Quicker inspection, more frequent inspection

Minimize fatigue risk, reliable downhole time

Managed assets – Pipe owners know their assets better

Reduced cost and NPT, more drilling days

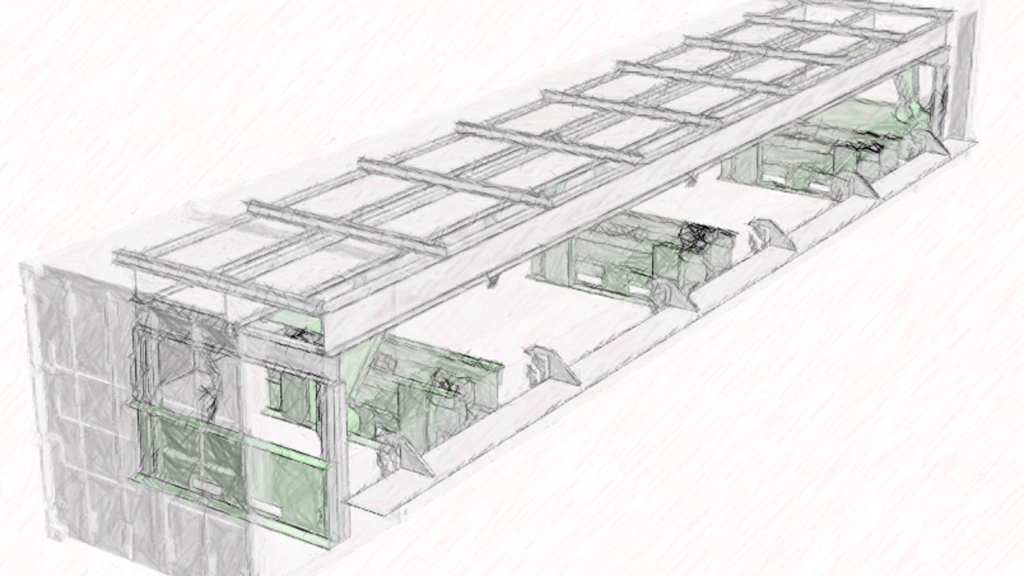

T.E.S.T Overview

Self-contained climate-controlled one-piece winch truck-ready packaging.

Robust design, fully automated internal tubular handling system

Surface Preparation

Fully automated laser ablation technology provides effective removal of dirt, rust, oil, & grease from the pipe surface

Telecentric Measurement

The confocal optical system produces up to 100 simultaneous real time measurements

Multi-Transducer Ultrasonic System

Provides upset-to-upset inspection coverage exceeds API requirements to meet industry demands.

True Wall Tech

Analytics system collects tube body volumetric data not attainable with current inspection methods.

The data collected is utilized in real time mechanical performance calculations.

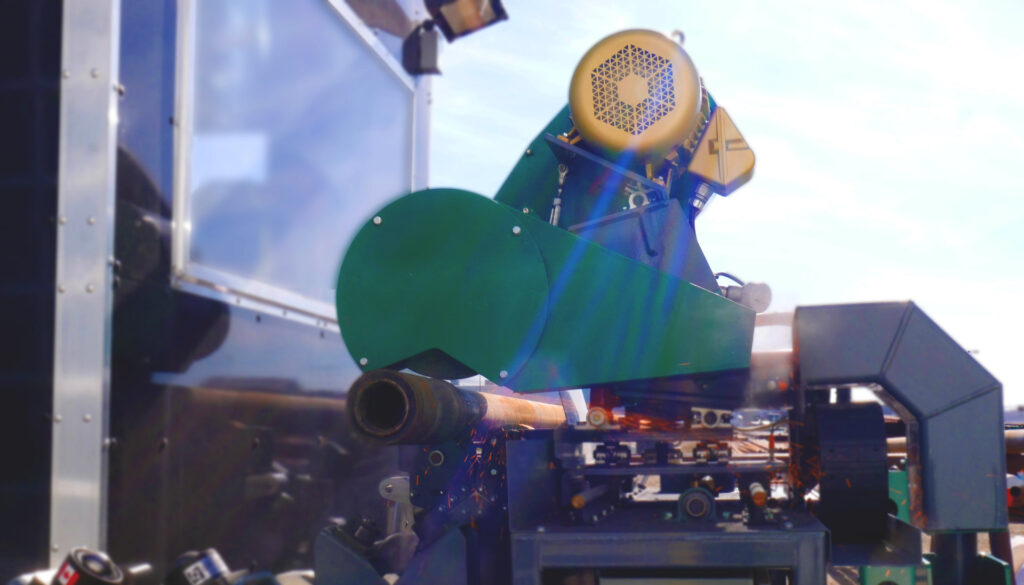

Gen II Hardfacing Unit

A new generation of hardfacing:

One-Piece Packaging – Self-sustained setup, minimize personal and non-productive hour

Grinding – Mitigate safety risk for operator, and improve output with a logic-controlled system

Induction Preheat – Replace open flame heating method, yield consistent quality of hardband application

Welding – Programmable tool joint size and wire type “recipes” result in precise repetitively controlled bandwidth and height dimension

Quality & Data – Pipe information and temperature records ready to export to laptop, tablet, and/or your cell phone at a finger click